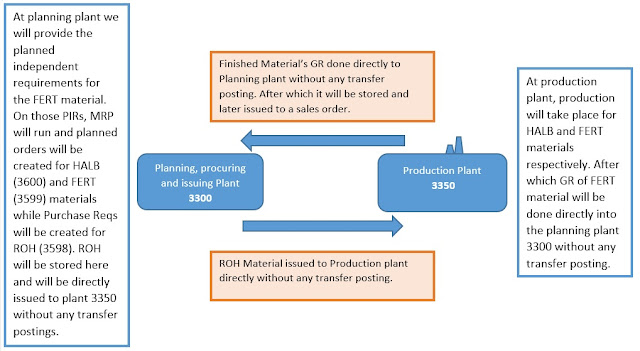

This document explains the steps required to configure a system for Production planning in a cross plant set-up. It has been observed that many members post questions with a bit of variation regarding this scenario. Hopefully this blog will address any current and future queries regarding this topic.

Cross plant production is one of the key parts of SAP – Production Planning, it is also know as production in alternative plant. In this document we will use Special procurement types 70 and 80 to address this scenario, thus eliminating the need of doing any transfer postings.

Prerequisites – Create Master Data i.e.

Material Master (FERT, HALB and ROH)

BOM (FERT and HALB)

Routing (FERT and HALB)

Work Centers

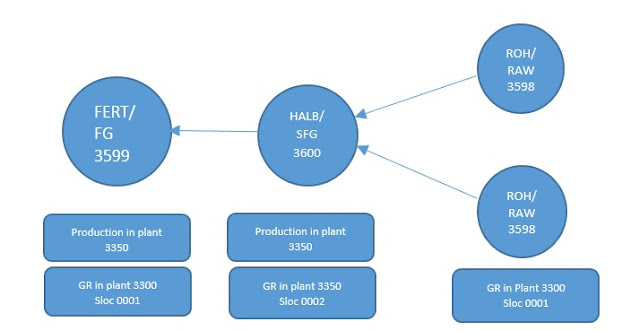

HALB will be created in 3350 plant, while FERT and ROH will exist in both plants by extending them to the other plant through MM01.

We will be working on MTS – Make to Stock strategy.

Scenario:

Cross plant production is one of the key parts of SAP – Production Planning, it is also know as production in alternative plant. In this document we will use Special procurement types 70 and 80 to address this scenario, thus eliminating the need of doing any transfer postings.

Prerequisites – Create Master Data i.e.

Material Master (FERT, HALB and ROH)

BOM (FERT and HALB)

Routing (FERT and HALB)

Work Centers

HALB will be created in 3350 plant, while FERT and ROH will exist in both plants by extending them to the other plant through MM01.

We will be working on MTS – Make to Stock strategy.

Only configuration required in this scenario is to configure special procurement types 70 and 80.

For plant 3300 we will use special procurement type 80. We will mention plant 3350 in special procurement section of [ Prod. Other plant ].

For plant 3350 we will use special procurement type 70. We will mention plant 3300 as issuing plant in the ‘As BOM component’ section. Make sure there’s a tick at the box of withdr.altern.plant (withdrawal from alternate plant).

Special procurement 70 will be assigned to HALB’s BOM component. We will select ROH material in the BOM and click on item (or press F7). T.Code CS02

Special procurement 80 will be assigned in FERT’s MRP 2 view in plant 3300. T.Code MM02

After completing all of the above tasks we will proceed with a real time test. For FERT material, stock of 50 already exists thus we will have to add this in our future calculations.

Now we will go to PIR planning table T.code MD61, and enter the value of 100. Make sure the date is not on a holiday.

You can double check the planned qty and its date in Schedule lines tab.

After running the MRP (T.Code MD02) we will go to stock requirement list of FERT material. Here you can see IndReq of 100 and planned order of 50 quantity. Reason being that 50 qty of FERT is already available in unrestricted stock, so that stock will be consumed first. You can also see supplying plant as 3350 because FERT material will be manufactured in plant 3350.

For FERT Material in plant 3350 (T.code MD04) you can see Planned order for 50 qty while 3300 plant is showing as planning plant.

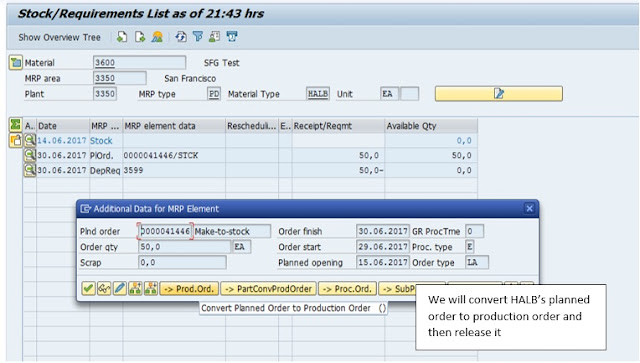

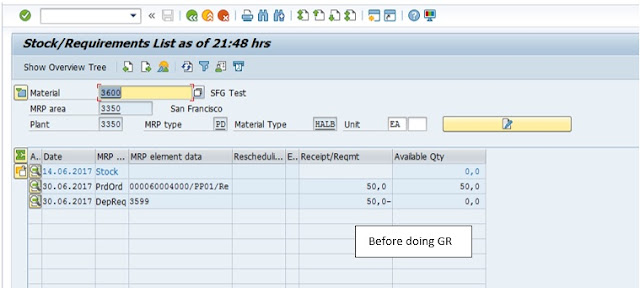

For HALB Material in plant 3350 you can see a planned order of quantity 50.

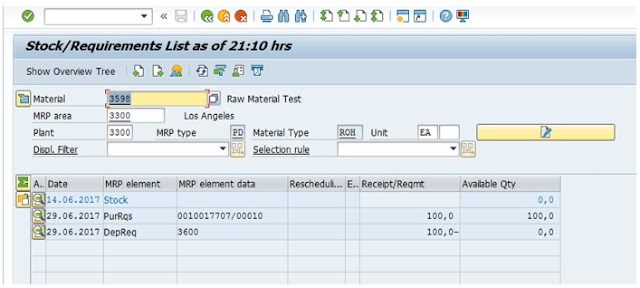

For ROH Material you can see DepReq of 100 and PurRqs of 100. That’s because in one HALB material 2 ROH materials are consumed.

Convert Purchase requisition of ROH to purchase order and do GR in plant 3300.

Convert planned order of HALB to production order.

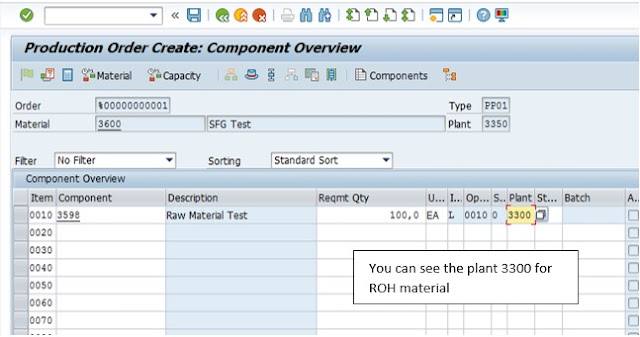

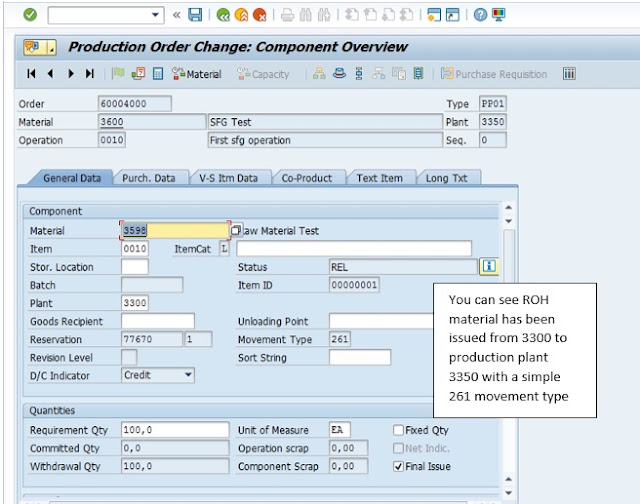

In component overview of HALB’s production order you can see 3300 plant for ROH material.

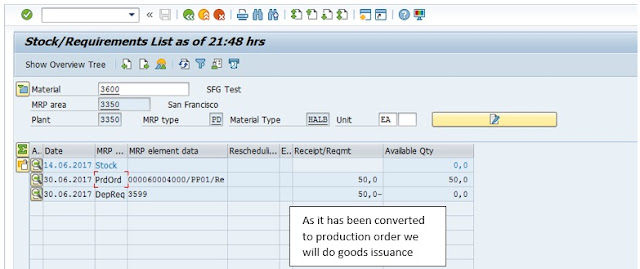

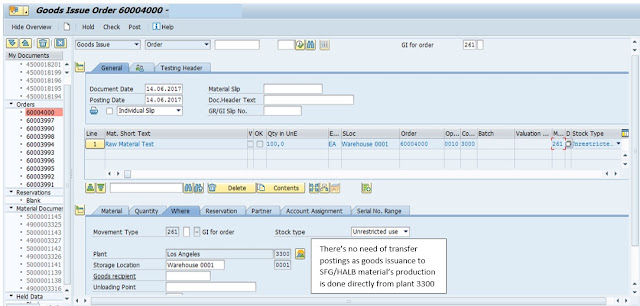

Now we will do goods issuance (Movement type 261) on the production order of HALB material.

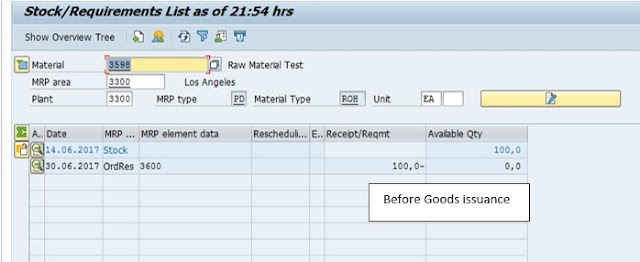

Before Goods issuance, ROH material stock is 100.

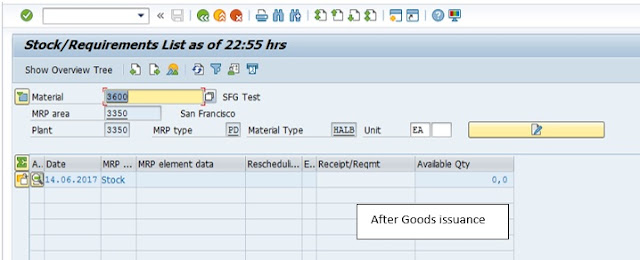

After Goods issuance, ROH material stock reduces to zero. Point to notice is that there were no transfer postings done.

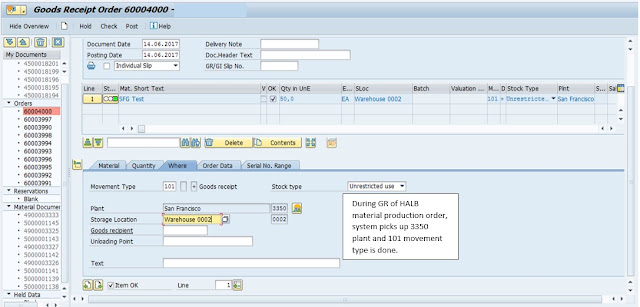

After doing Confirmation of HALB’s production order we will do Goods Receipt of HALB material.

Before GR of HALB

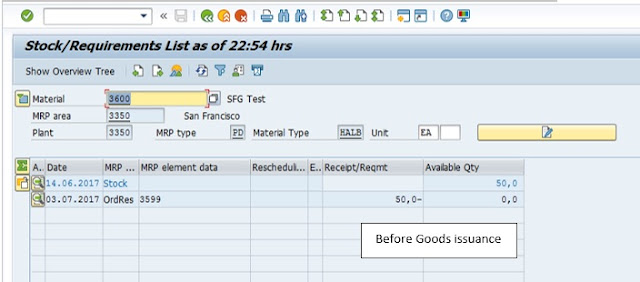

After GR of HALB. 50 quantity has been added to stock.

After GR of HALB material, we will convert planned order of FERT to Production order. Note supplying plant is 3350.

Planning plant and MRP area for FERT’s production order is coming as 3300

Now we will do goods issuance to FERT’s production order. 261 movement type is done.

Now we will do goods issuance to FERT’s production order. 261 movement type is done.

In FERT material’s Production order HALB’s withdrawal quantity is coming as 50

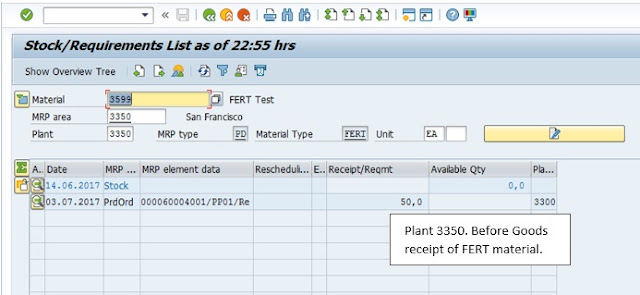

After confirmation of production order we will do GR of FERT material.

But before that you can see for plant 3300, FERT’s material Stock/requirement list is showing 3350 as supplying plant while for plant 3350 Stock/requirement list is showing 3300 as planning plant.

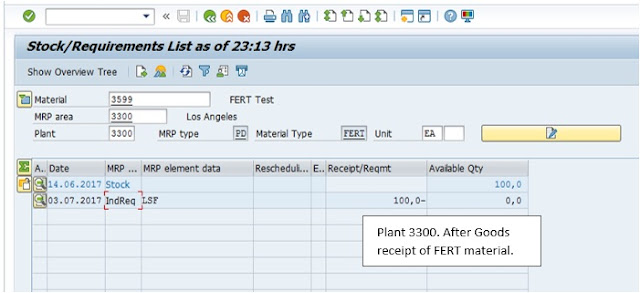

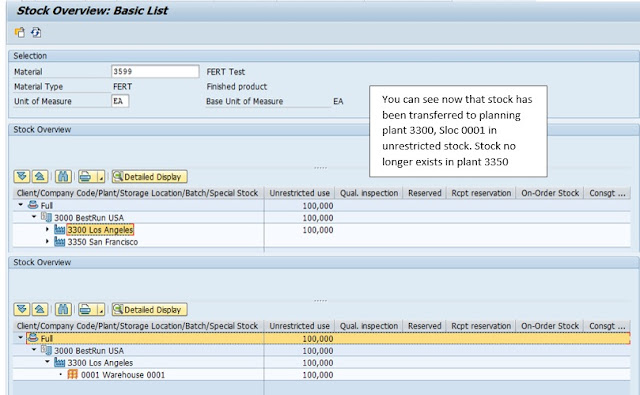

We will go to MIGO and do GR of FERT’s production order. It will be done directly to 3300 plant 0001 Sloc without the need of any transfer postings.

After GR, stock in 3300 plant has increased from 50 to 100

After GR, stock in 3350 plant has decreased to zero.

You can see in Stock overview list (T.Code MMBE) that stock in ‘unrestricted use’ is 100 for plant 3300 in 0001 Sloc, while stock is Zero for plant 3350. Production Cost will be collected in production plant 3350.

Nice Post. I like your blog. Thanks for Sharing.

ReplyDeleteSAP PP Course in Noida

Production Planning and Control are very important for success of an operation unit. For effective operation in a manufacturing unit, it is essential to integrate the production ...

ReplyDeleteProduction planning and control

Agaram infotech

“Production planning and control involves generally the organization and planning of the manufacturing process. Specifically, it consists of the planning of the routing, scheduling, dispatching and inspection, co-ordination and the control of materials, methods, machines, tooling and operating times.

ReplyDeleteProduction planning and control

Agaram infotech

Wonderful Information have been Shared...

ReplyDeleteSAP Training in Chennai

SAP ABAP Training in Chennai

SAP BASIS Training in Chennai

SAP FICO Training in Chennai

SAP PP Training in Chennai

SAP PM Training in Chennai

SAP QM Training in Chennai

SAP SD Training in Chennai

SAP MM Training in Chennai

SAP MDG Training in Chennai

Nice blog..

ReplyDeleteSAP ABAP on Hana training from india

SAP ABAP training from india

SAP BW on Hana training from india

SAP mm training from india

SAP pm training from india

SAP PP training from india