Purpose: The Materials Management (MM) component supports the procurement of manufacturer-specific parts or materials from different vendors. If you implement the functions for manufacturer part number (MPN) processing, you can also process goods receipt inspections for manufacturer-specific parts or materials in the Quality Management (QM) component.

We Can

◉ Block or release a request to deliver

manufacturer-specific parts or materials in a quality info record

◉ Waive the inspection requirement for

manufacturer-specific parts or materials (provided the vendor and manufacturer

have certified QM systems in use)

◉ Use manufacturer-specific inspection

plans to inspect the manufacturer parts or materials

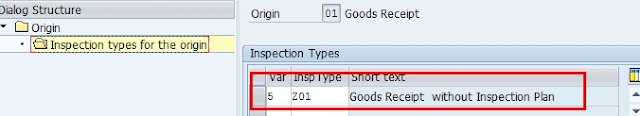

1.Configuration Requirement

Create Profile Part Profile

T Code: OMPN

We Can

◉ Block or release a request to deliver

manufacturer-specific parts or materials in a quality info record

◉ Waive the inspection requirement for

manufacturer-specific parts or materials (provided the vendor and manufacturer

have certified QM systems in use)

◉ Use manufacturer-specific inspection

plans to inspect the manufacturer parts or materials

1.Configuration Requirement

Create Profile Part Profile

T Code: OMPN

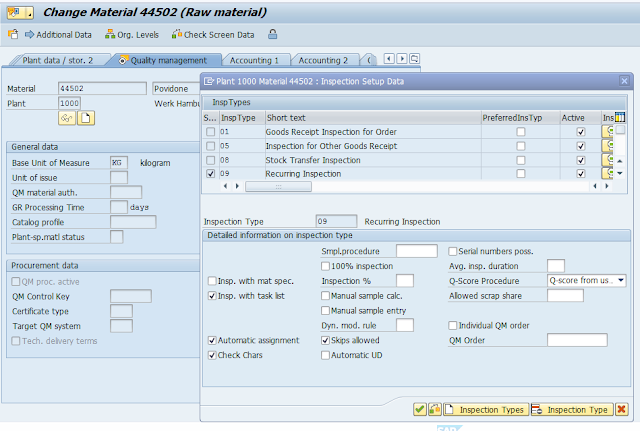

2.Assign this profile for Internal Material

Create Manufacturer Part in MM01

Part – 1

This is procured from 1st Manufacturer: MF-1000

Create Material with (Material Type- HERS)

Part – 2

This is procured from 2nd Manufacturer: MF-1001

Create Material with (Material Type- HERS)

3. Create APML list

If you wish to influence the precise source or quality of materials, you can tell the vendor from whom you want to procure a material which manufacturer the material is to be supplied by and the part number used by that manufacturer. You can also tell your vendor exactly which of a manufacturer’s plants is to supply the material you wish to procure. The manufacturer’s part number (MPN) and description, as well as the specific manufacturing plant (if applicable), with the help of APML List.

T Code: MP01

4. Create Q-info Record

Beacuse of certain quality reason we Block Manufacturer MF-1001 for creation of Purchase order.

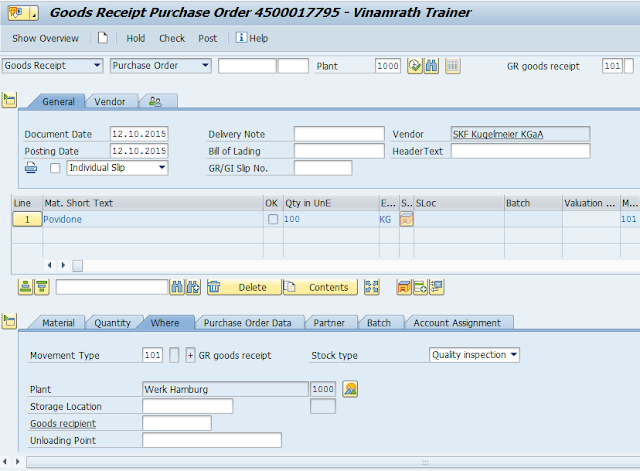

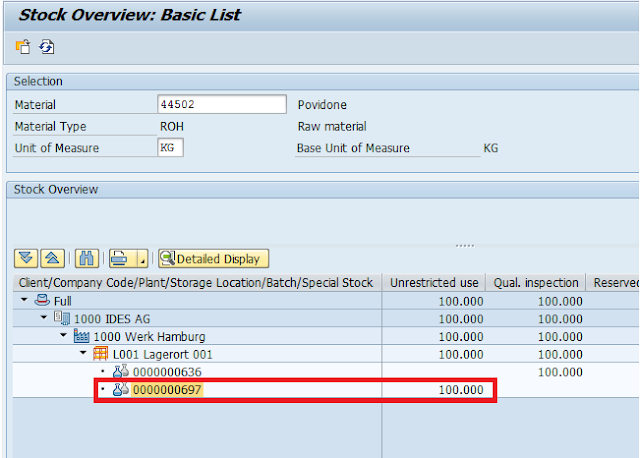

5. PO

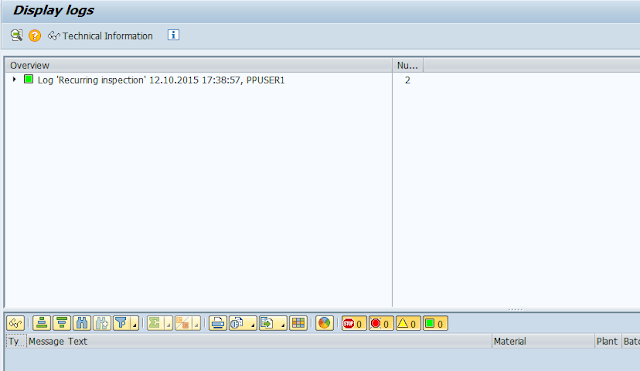

Then at the time Po Creation it gives the error as shown in below screen shot

Above screen shows that material is blocked for procurement for quality reasons.

This scenario conclude that Manufacturer quality is controlled by this way.