When an inspection lot is created, the system uses the inspection lot origin to determine how the inspection lot will be processed.

Suppose as per the business requirement inspection type will be use for the material for which result recording is not required and it will have the Post to inspection stock and Auto UD indicator active. I am creating customize Inspection Type Z01 which is a copy of 01.

1. SPRO > Quality Management > Quality Inspection > Inspection Lot Creation > Maintain Inspection Type.

Suppose as per the business requirement inspection type will be use for the material for which result recording is not required and it will have the Post to inspection stock and Auto UD indicator active. I am creating customize Inspection Type Z01 which is a copy of 01.

1. SPRO > Quality Management > Quality Inspection > Inspection Lot Creation > Maintain Inspection Type.

Select the Inspection type 01 and Click on Copy.

Maintain the Inspection Type Z01 and Description.

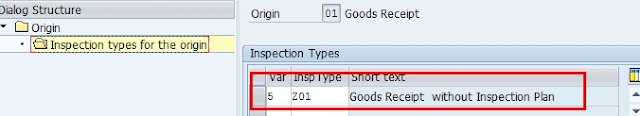

2. SPRO > Quality Management > Quality Inspection > Inspection Lot Creation > Maintain Inspection Lot Origin and Assign Inspection Type.

Select the Lot Origin 01 and Click on Inspection type for the Origin.

Click on New Entries

Maintain Inspection Type Z01.

3. SPRO > Quality Management > Quality Inspection > Inspection Lot Creation > Define Default Values for Inspection Type.

Select the Inspection type 01 and click on copy.

Maintain the Inspection Type Z01 and field maintain here will have default value for the inspection type.

4. Assign Inspection Type to the Material.

Customize Inspection type will work only when Preferred Ins Type Indicator is activated.

Detailed information on inspection type Z01 will have default value as maintain in Define Default Values for Inspection Type.

Very good detailed information thank you.

ReplyDelete