As we know about the module MM, FI and SD in SAP ERP.

MM stands for Material Management, FI standard for Financial Accounting, SD stands for Sales and Distribution.

These two modules FI and SD is very much integrated with MM modules. As we are in MM module, we should know about the integration point.

Here in my blog you can get the knowledge for integration between MM-FI, MM-SD and SD-FI.

We know MM modules means procure to pay process, FI module means financial statement and payment process, SD module means sale to customer process.

Most of the manufacturing business logic is stands for 3 things BUY-MAKE-SALE

It means an organization buy a raw material/product from a vendor, then he makes from this raw material/product to finished material/product, then he sale the finished material/product to a customer.

In that 3 part the 3 module are integrate each other.

MM stands for Material Management, FI standard for Financial Accounting, SD stands for Sales and Distribution.

These two modules FI and SD is very much integrated with MM modules. As we are in MM module, we should know about the integration point.

Here in my blog you can get the knowledge for integration between MM-FI, MM-SD and SD-FI.

We know MM modules means procure to pay process, FI module means financial statement and payment process, SD module means sale to customer process.

Most of the manufacturing business logic is stands for 3 things BUY-MAKE-SALE

It means an organization buy a raw material/product from a vendor, then he makes from this raw material/product to finished material/product, then he sale the finished material/product to a customer.

In that 3 part the 3 module are integrate each other.

⟾ When the organization buy a raw material/product then its coming into warehouse stock, which is goes to MM modules. And because of the organization has buy something from a vendor, he has to pay for this to the vendor, which id goes to FI modules.

⟾ When the organization make the raw material to finished material, at that time the organization needs a subcontractor vendor, who will make the subcontracting process. Then process from raw material to finished material, it goes to MM module. And the organization has to pay the subcontracting vendor, this will goes to FI module.

⟾ When the organization sale the finished material to customer, They have to proceed the sales process (Like as sales order, delivery, billing etc), its goes to SD modules. At the time finish goods stock is decreased from warehouse, which is goes to MM module. We sale the finished material to customer, so customer will pay for this finish material, the payment terms goes to FI modules.

MM-FI Integration

In this part, we learn about MM-FI integration points. When we do a movement for a material, if the movement is account effect-able, then it will post a account entry in FI.

Lets discuss about how the accounting entry are posted and how you can do the configuration.

We have a material master data in our procurement process.

In material master, we stored all information for a certain material. Like as material type, material group, purchasing information, sale and distribution information etc etc.

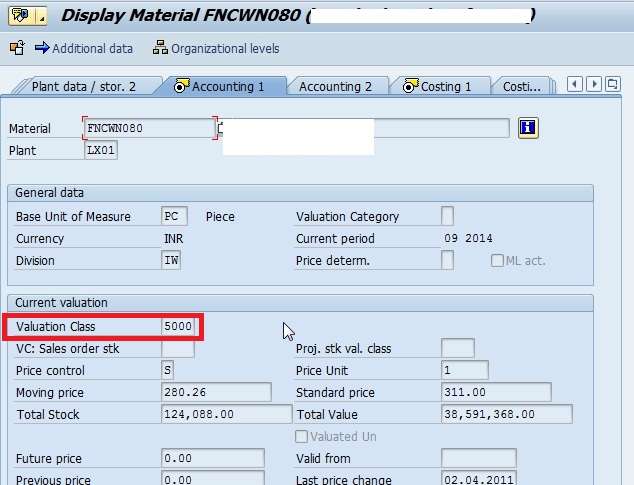

The valuation class (in accounting 1 view) is most important for automatic account posting purpose.

We can see the valuation class for individual material from t-code MM03.

Valuation class is used to group together several material with their same attributes, so that we can carry the same account determination for various material.

Every material has a valuation class, many materials can contain same valuation class.

As we know the valuation class is link with material type via account category reference.

You can see the blog to understand about material type, account category reference and valuation class.

The valuation class will be for Raw material, Semi-finished, finished goods. We can differentiate valuation class as per our business requirement.

Valuation class and Movement type is used for the G/L determination.

Movement type is used for all types of material movement. Suppose if you receive a material from a vendor, a movement is happens for the movement.

If we transfer a material from one location to another, a movement type is happens for the movement.

It means, whenever we do a off-setting entry, a movement type will be created for that.

For various movement type SAP defines a G/L account for the material movement.

Lets discuss about an account entry for a movement type.

When we do a goods receipt, the movement type happens is 101. And SAP designed as per business process the account entry will

Inventory A/C debit

GR/IR A/C credit.

We know about these account, Inventory a/c for material master and GR/IR account is a provision account for vendor.

The all account entry is done via automatic account posting.

SPRO-IMG-MM-Valuation and Account Assignment-Account Determination-Account Determination Without Wizard-Configure Automatic Postings (t-code OMWB)

Direct t-code OBYC.

You can find the all details of automatic account determination with this document Automatic Account Determination.

For different different movement type, the account entry is done via different transaction event key.

For example

If any movement type hits the inventory entry then it will hit the BSX transaction event key..

If any movement type hits the off-settings entry then its hit the GBB transaction event key.

If any movement type hits the provision entry then its hit the WRX transaction event key.

If you noticed the transaction key GBB, then you can find the a lots of account modifier are used for various movement type.

We can’t remember the all account modifier at all, for this purpose SAP introduce Simulation Mode. Using simulation mode, you can easily identify the account modifier which is used for GBB.

Path = SPRO-IMG-Materials Management-Valuation and Account Assignment-Account Determination-Account Determination Without Wizard-Configure Automatic Postings

T-code OMWB

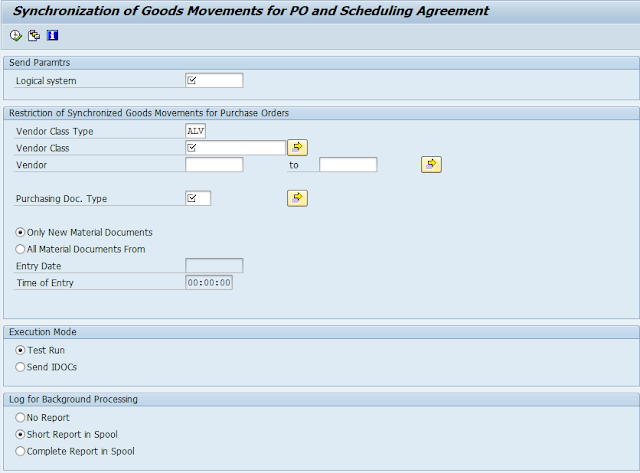

Set up the simulation criteria as per your requirement.

Set up the Application Area, Input Mode, Account Check. Then press simulation

You can see the all G/L account uses with all transaction event key and account modifier for this particular movement type.

In this way when we post a movement type in MM module, its also update in FI module.

In short, we can say the main point of MM-FI integration is OBYC

From MM side its Valuation class and for FI side its G/L account. When we do a movement type, the movement type finds the valuation class for the material, and post the amount to this G/L account which is assigned to this particular valuation class.

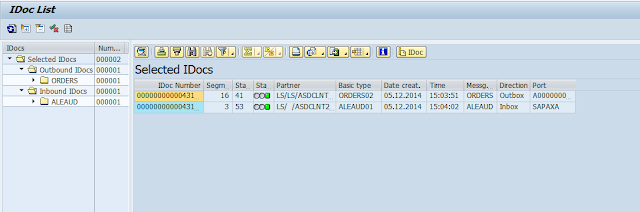

SD-FI Integration

In this part, we learn about SD and FI integration point.

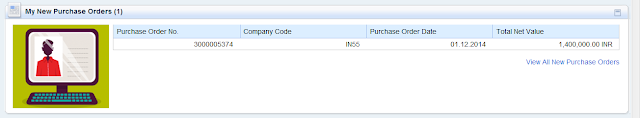

Whenever we sale a finish material to customer, then the customer have to pay for that. We send a bill to customer.

In that position all billing document which is happens to sales and distribution module will be posted into FI module.

The account entry of respect to the billing always have two sides

One side is Customer account and other side will be revenue account.

For example:

Customer A/c Debit

Revenue A/c Credit.

AS per SD module, the customer account will be picked from customer master data, which is maintained from SD module.

We just need to configure the revenue account and if there any discount and surcharges account.

We have to do that via access sequence, access sequence is just a SAP terminology to determine the G/L accounts.

SAP provides 5 ways to determine G/L account in SD modules.

These are

1. Cust.Grp/MaterialGrp/AcctKey

2. Cust.Grp/Account Key

3. Material Grp/Acct Key

4. General

5. Acct Key

The assigned G/L accounts are used to post the discount and revenue and any kind of surcharges.

To configure this

Go to Path = SPRO-IMG-Sales and Distribution-Basic Functions-Account Assignment/Costing-Revenue Account Determination-Assign G/L Accounts

T-code = VKOA

You can see the below screen and you can also see the default table and description for above 5 ways.

First system checks the first table entry Cust.Grp/MaterialGrp/AcctKey. If any G/L maintained here then system will go to the transaction and the particular billing document, then system search the combination of customer group and material group. If system will find any G/L, then system will go through the G/L, if system doesn’t find the G/L, then it will search the next table.

Customer group is maintained in Customer master Data, Material Group is maintained in Material Master Data, Account key is maintained for condition type in pricing procedure.

Lets maintain One G/L account for material group and account key combination.

Double click on the Material Grp/Acct Key

I have maintained the G/L for this combination. here AAG is the material grp.

Whenever system search the table and find the combination for transaction, then system will debit customer account and credit to this account (180033)

The account key determine that it is a revenue or discount or surcharges.

Press F4 on the Account Key field, you can see the all account keys.

The account keys are also maintained in calculation schema in Pricing procedure.

Path = SPRO-IMG-Sales and Distribution-Basic Functions-Pricing-Pricing Control-Define And Assign Pricing Procedures-Maintain pricing procedures

In this way SD and FI are integrated each other.